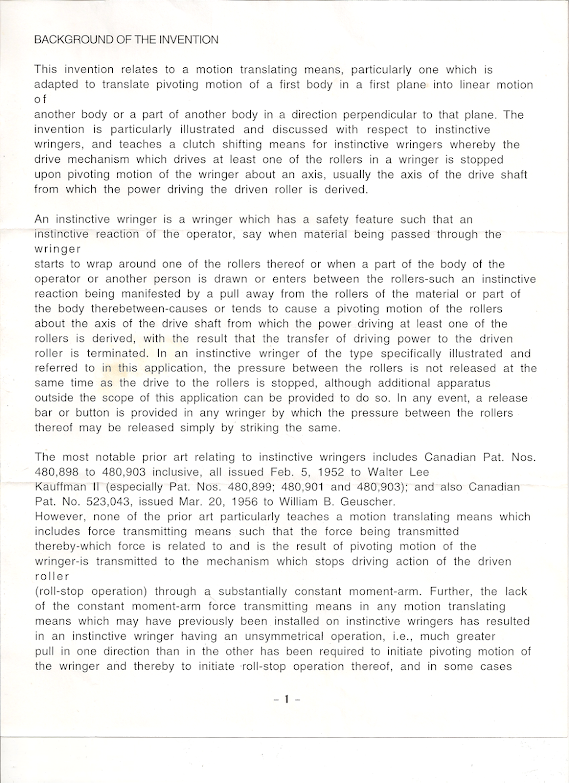

Walter Lee Kauffman 2nd, born in 1895 into the era of mechanical technology. He was a Mechanical Engineer, educated at University of Washington, albeit, he never completed college, interrupted by World War I and a restless nature. Over the next 30 years starting in 1930, Walter Kauffman created thousands of innovations and refinements resulting in over 100 patents most relating to the process of washing and drying clothes but also military products and other components. These included:

- Clothes Wringer Manufacturing (52)

- Advanced Safety Features for Wringers (15)

- Clothes Dryer (8)

- Other components, like bearings, bonding, manufacturing rubber, couplers, gears etc (20)

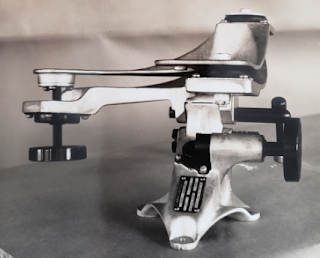

- Nordon Bomb Sight Mount

- .30 caliper machine gun mount

Cars were always his first love. But one of his first ventures in 1920s shortly after he moved to Youngstown involved manufacturing cast iron sinks and consulting with a company that made pumps. This exposed him to the process and tools of washing and drying clothes.

During this period, the process of cleaning clothes was pretty basic. You would wash them in a sink, in the process, you might scrub them against a wash board, then squeeze the water from the clothes using a wringer and dry them, usually by hanging them outdoors on a clothes line until they dried.

The traditional washboard is usually constructed with a rectangular wooden frame in which are mounted a series of ridges or corrugations for the clothing to be rubbed upon. For 19th-century washboards, the ridges were often of wood; by the 20th century, ridges of metal were more common. A “fluted” metal washboard was patented in the United States by Stephen Rust in 1833.[1] Zinc washboards were manufactured in the United States from the middle of the 19th century. In the late 20th century and early 21st century, ridges of galvanized steel are most common.

The earlier wringers consisted of a wooden frame with two wooden rollers geared to a crank. The wringer was clamped onto a cast iron sink. Clothes were washed in the sink and then lifted from the soapy water of the sink and run between the wooden rollers which squeezed water from the clothes back into the sink as the clothes dropped into a clothes basket. These clothes then were hung on the clothes line to dry.

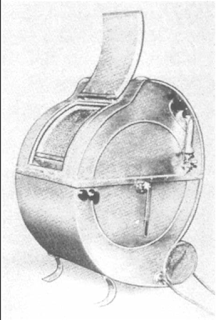

It was French inventor, Pochons, who in 1799 created the ventilator – and it was this initial design that became the early antecedent of the tumble dryer. Essentially a metal drum with holes, clothing was placed inside the drum and dried over an open fire with a hand cranking system.

It was a design that worked, but it did suffer the major disadvantage of leaving clothes smelling of smoke and occasionally dusted in soot. Its basic design, however – a ventilator system comprising of a metal drum with holes – remains the foundation of all tumble dryers.

American inventor, George Sampson, patented the first name ‘clothes dryer’ in 1892. It took the basics of Pochon’s original design and dramatically improved on them – he came up with the idea of a metal drum with a rack that dried clothes but away from the main source of heat. Replacing the original open fire concept with a stove, it made the dryer not only more efficacious, but also safer.

Even as early as 1915, it was possible for consumers to purchase early design tumble dryers for their home. As with any new technology, however, it came at a price, and the luxury of being able to dry your clothes so quickly and conveniently came with a hefty price tag.

The 1940s saw tumble dryer sales go stratospheric, and it wasn’t long before a battle commenced amongst various manufacturers and brands keen to capitalize on the dryer’s success. For the consumer, this had the advantage of driving the price down even more.

The more “modern” process started with agitation, squeezing, and spinning. Driving a device to agitate is much like a piston and crankshaft. Spinning is like driving a rear wheel. Walter was right at home, just a slight adaptation from his cars. As mentioned, he had a cast iron sink manufacturing company. He developed a process to apply bake enamel paint onto the sinks. He sold off this process to Dupont.

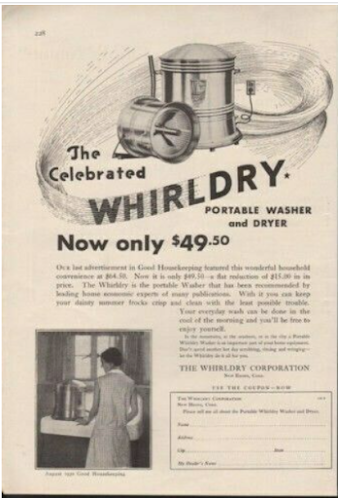

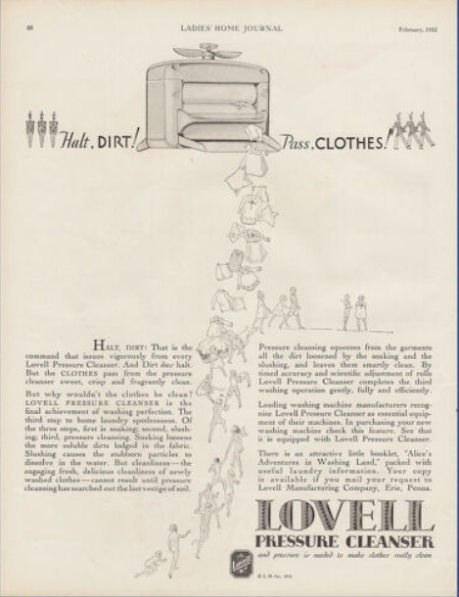

Lovell Manufacturing in Erie, PA was a manufacturer in the industry. They had built wooden hand operated wringers for years as well as other wood products like hockey sticks and even mouse traps. In 1930, they introduced a device called the Pressure Cleanser. It was a replacement to their earlier hand operated wringer. It provided an electric motor to power the rollers reducing much of the labor. It would be mounted on a pedestal on the corner of a dual sink.

Electric powered wringers were a great advancement for clothes washing. However, they were inherently dangerous. Inserting wet clothes between two spinning rollers with your hands was prone to catching your hands between the rollers. Even worse, “catching your tit in a wringer” became a widely used expression for “in a bad way” or a “bad situation”.

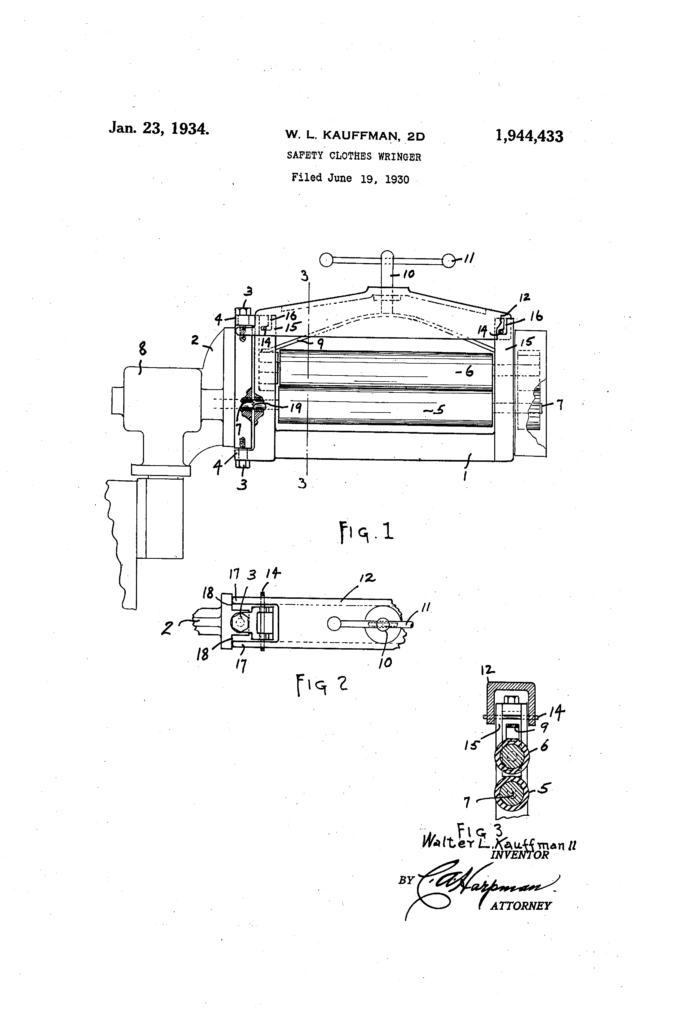

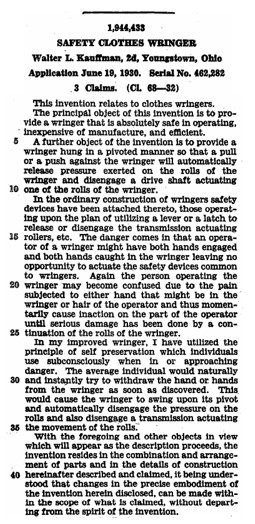

Walter had a solution, the Instinctive Safety Clothes Wringer. While Wringers had a safety lever on them that the operator could press when catching their fingers, hair or other body parts in the wringer, it did not work effectively if you caught both hands nor in the moment of panic was it intuitive for the operator.

Walter reasoned that the likely motion was to pull the hands or objects away from the wringer. So, he designed it so that any motion to pull or push the wringer would cause it to swing away from a pedestal and in doing so, would stop the operation of the rollers and disengage them from the drive allowing the rollers to freely roll and the operator to free themselves from the wringer rollers. He applied for a patent for this on June 19, 1930 while living in Youngstown, Ohio. When Lovell Manufacturing Company became aware of it, they reached out to him to join their organization in Erie, PA.

Once at Lovell, Walter obtains a number of other patents on manufacturing processes including methods for making parts needed for the wringers. He adds a safety lever, then a bar, reversing gears, rapid releases, and more all supporting the basic concept. Over the next years his patents drive Lovell’s business proving wringers to Sears, Whirlpool, GE and others who manufacture the Washing Machines thru the 1930’s, 40s and 50s.

===========================================

Let’s look at the history of clothes driers. By 1930, the process of drying clothes has not progressed very far. Tumble dryers lack a reliable source of heat. Open fires are problematic, impossible in the home and impractical in an external building. People relied on outdoor clothes lines or inside systems to dry clothes.

Walter’s first patent on dryers came in 1931. It was an improvement on a pressure dryer. Basically the clothes were placed in a bag and hydraulically squeezed forcing the moisture out of the clothes and into a discharge pipe. The present invention is designed to improve the manner of securing and adjusting the cover with relation to the receptacle so as to facilitate the insertion and removal of the clothes and for directing the discharge of water from the receptacle.

This process of drying clothes did not appear to gain much following in the market. By 1936, the tumbler type dryer has been widely accepted in the market and in 1938 another inventor, J Ross Moore, further refined the tumble dryer’s design that made it possible for the general public to purchase the dryer at a more cost effective and pocket friendly price. Called June Day, it came in gas and electric models.

Walter’s next patents for Dryers would come in 1946.

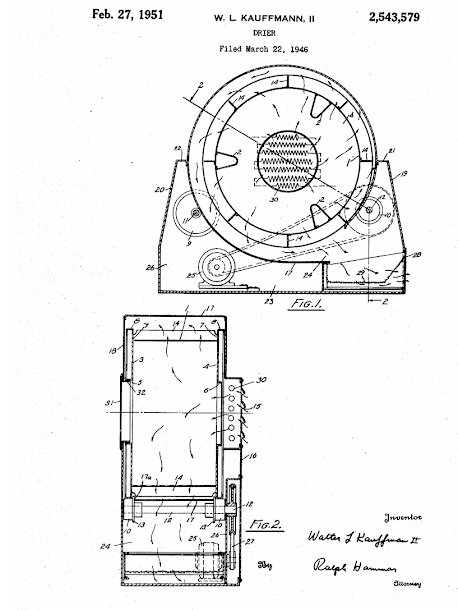

Patent 2543579 filed Mar 22, 1946 – Dryer.

This invention is intended to simplify the construction of tumbler type clothes driers by utilizing the drum as the blower for circulating air through the drum. In one form the heater radiates through one end of the drum and the door for loading and unloading clothes is in the other end of the drum.

He quickly follows with additional patents.

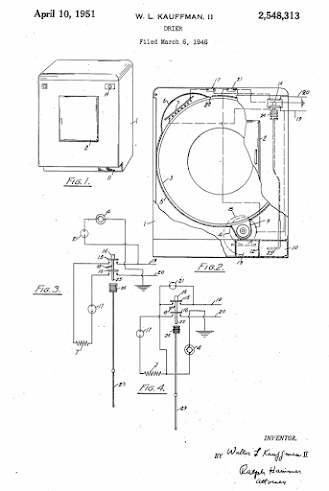

Patent 2548313 filed Mar 6, 1946 – Dryer.

In tumbler type clothes driers at the end of the drying cycle, the clothes are hot and uncomfortable to remove. This invention is intended to prevent this by continuing the rotation of the drum after the header is shut off. In a preferred form the rotation of the drum is started after the heater has warmed the drum to a point at which drying can efficiently start.

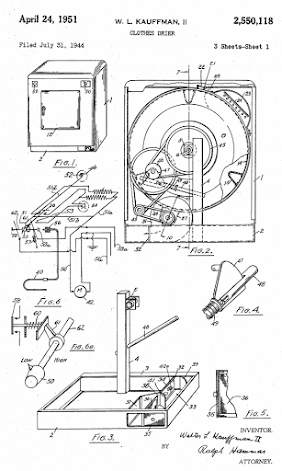

Patent 2550118 filed July 31, 1944 – Dryer.

The object of the invention is to provide an improved construction and arrangement in driers of this type having and improved arrangement for handling lint and simplified control.

Patent 25583850 filed January 29, 1948 – Dryer.

Tumbler type clothes driers have been made with an automatic control cycle responsive to the exhaust air temperatures. Among the problems encountered have been the unwanted accumulation of lint and the high temperature of the clothes at the end of the drying cycle. This invention is intended to solve these problems through a lint trap at the point of discharge from the drum and by a controlled over run at the end of the drying cycle giving the dried clothes a chance to cool.

Patent 2623299 filed June 28, 1948 – Dryer.

In tumbler type clothes driers the lint dislodged during washing is released as the clothes are dried and is blown out with the exhaust air. Although the quantity of lint is not large, it is a nuisance. This invention is intended to provide a centrifugal lint trap. A bypass is provided in case the lint trap is blocked.

If you look at your dryer today, you will see Walter’s inventions are still in place.

- Hot air entering the drum from the rear,

- Drum continues to rotate periodically following completion of the drying cycle

- Centrifugal lint trap with bypass for clogs

- Automatic control cycles

Walter Lee Kauffman was part of a team of engineers who worked with the Defense Department during WWII to improve our military weaponry.

Norden Bombsight

WWII’s menacing B-29 Superfortresses menaced the Japanese over Burma, Manchuria and Japan. Design engineers at a blossoming Erie Industry – Lord Manufacturing Company – played a crucial role in developing the bomber that ended WWII. These engineers shouldered the responsibility for developing vibration control systems that both helped keep the planes in the air and helped deliver their deadly payload precisely to enemy targets.

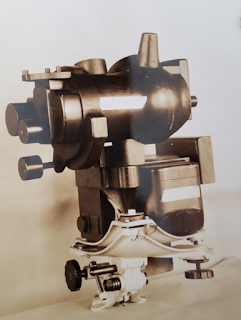

Leon Wallerstein and Walter Kauffman helped design the mounting device for the sensitive, top-secret Norden bombsight in the bomber’s glass-enclosed nose. The bombsight itself was highly classified. They used to take it out of the plane after landing and put it under guard. What they needed when they began designing the plane was a mount that would support the bombsight and isolate it from aircraft vibration. they had to have a good, steady sight to determine when the bombs should be released. What they came up with were three mounting plate forms comprised of rubber bonded to metal with the rubber isolating the bombsight from the vibration in the plane and metal mount.

.30 Caliper Machine Gun Mount

Walter Kauffman’s redesign work was done on pintle of the .30 caliper machine gun mount. Here three pounds of bar steel, formerly necessary for every pintle, were replaced by very little over two pounds of sheet steel, and machining time was reduced from an hour and in half to less than five minutes. Add up the material, machine and man-hours saved on these developments and multiply them by the hundreds of thousands in quantities in which these items are required by our armed forces and their importance is readily apparent, Col Reedall said.

Award

Bomb Sight

Bomb Sight Mount

Walter was always the inventor. I remember as a child being on a trip with the family to Florida. We stopped along the Pennsylvania Turnpike because Dad had an idea. He used the payphone (for you youngsters, we did not always have a cell phone) and called the office. It seemed like hours before he was done explaining his latest idea.

He was always diddling with something, like a better mousetrap, or the design of the pillars for the house. He had a design for flexible joints to allow a cover on the swimming pool sway with the wind.

From NKB – He was always thinking of better ways to improve things! Remember when he had a house designed to build on the orchard with the swimming pool as the center of the first floor? He brought the plans home proudly and presented them to Mom and she had a conniption! I thought it was a wonderful idea myself. I think the blueprints were hidden in your closet. After that we put the pool in that spot!

A Technical Discussion of the Instinctive Wringer